How does Leiyuan Factory Control the Quality of GSTank?

2016-10-28

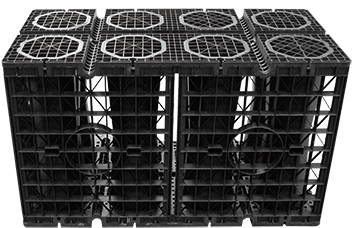

The GSTANK is a structural lightweight modular tank system used to construct underground water storage for various applications. It is ideal for storm water detention and also for long-term rainwater storage. The rainwater harvest modules is become more and more popular and favored by customers from domestic to foreign since it is came out. The reason why so many customers love this kind of rainwater harvesting systems from Leiyuan company is not only because of the design but also because the factory is strictly control the quality, how does the factory do that? Below is the answers:

1.Use high-purity raw materials

GSTANK is made of high-purity regenerated PP polypropylene, and the factory are very serious on the raw materials. Each plastics materials have their own characteristics to ratio, Leiyuan is more carefully on the purchase of raw materials, each batch of material will be observed from the color first. The plastic raw materials must be burning up and through the flame to determine the quality of the material. With this kind of strictly selection on the raw materials, our GS TANK can reach the service life of more than 40 years.

2. Introduction of new equipment

Leiyuan purchased a large scale equipment-injection molding machine for rainwater harvesting module production this year. This kind of machine can made the thermoplastic or thermosetting plastics material into various shapes of plastic products by using plastic molding mold. The clampling force of the new machine can even reach 8500KN. The large scale equipment injection molding machine has below excellent features. By adopting the new machine, the rate of finished products is increased substantially and the quality is better and more stable. Before adopting the new machine, the largest length of rainwater drainage soakaway crates Leiyuan can produce is only-800mm. But now length above 1000mm is already available according to customer’s request. Our new products M2016B is the newest design, the size is 1200mmx600x700mm. Through this upgrade of equipment, Leiyuan can offer multiple sizes of tanks which could adapt to the demand of different engineering.

3. Improve production technology

The factory upgrading the production line into robot production, which change “people controlled machine” into “machine control people”. The time of producing products from the injection molding machine is more fixed so that the production efficiency is improved. Meanwhile by the application of robot production, the soakaway crate product is more resistance to fall. The compressive strength is well guaranteed. At the same time, the factory Upgrade packing machine, which can add special iron card slot on the packing machine, which is conducive to product packaging more neatly.

4. Use compression testing machine

Factory own its compression machine. Compression testing center takes 500RMB for one time of press. By application of compression machine. Each producing of 50CBM products the machine will be random press of the products, the average compressive strength of each single product is 10 tons.

Above is how Leiyuan factory control the quality to make sure the every pieces of rainwater harvest module can be its best quality. Besides all above, our GS TANK also is certified by American TRI testing institution, meeting the HS-20 standard in US market. And Leiyuan will continued to improve and progress itself now and future so that the best quality of rainwater harvesting module product and best service can be bring to our customers.

PrécédentHow Dose GSTANK Help You Save Cost?

ProchaineGSGrid Attract Farm Owner Become Our Distributor, Are You the Next One?

Message